CII-Connected Solutions on Supply Chain Consulting helps a reputed FMCG improve its Forecast Accuracy by 20%

22

Jul

Solution Offered:

Implementation of Demand Forecasting and Replenishment Planning solution, which was integrated with leading ERP solution. The main objective of the solution was to improve forecasting and also to have effective inventory control across various locations. The solution was implemented in 20 weeks.

Demand Planning before Implementation:

The Depot Manager would generate the demand for the next quarter and share the numbers to the Division or Region head, who in turn would moderate the quantities and share it with the marketing team. The marketing team would consolidate all the files. Based on the inputs from Depot Managers, previous year trend and the Inventory holding at Depot, the demand is generated for India as well as Depots. Generated demand is shared with the entire team. This entire demand planning process was done using multiple Excel files.

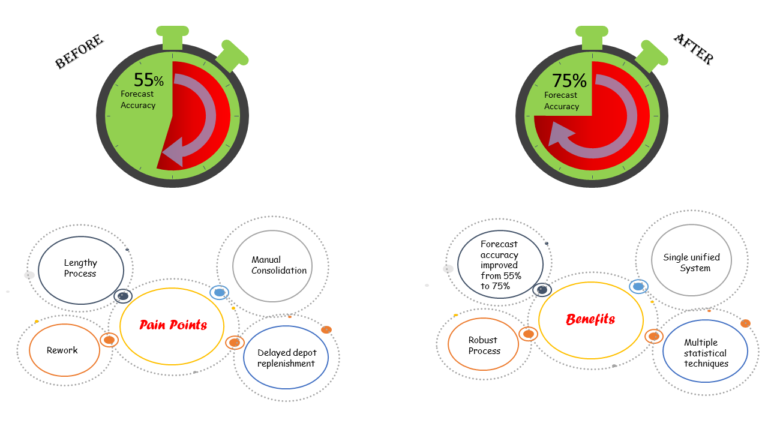

Challenges faced before Implementation:

- A lengthy process, time-consuming and delayed Depot replenishment.

- Manual consolidation of demand data at each level.

- Rework and moderations based on assumptions and no statistical models

- Manual adjustment on material available dates at Depots became a cumbersome activity.

- Demand planning for promotional products was difficult as they were not considered as demand drivers.

Demand Planning after Implementation:

Past sales history of the Products is considered and various statistical techniques are run to arrive at the Forecast quantities. Among the various techniques, the tool automatically picked up the best fit technique based on the MAPE (Mean Absolute Percentage Error). This was then released to the depot managers to moderate the statistically generated forecast. Collaboration mechanism was put in place across to arrive at a consensus forecast based on a bottom-up and top-down approach.

How did it help?

- Providing advance visibility of product demand.

- It provides the Depot Managers baseline forecast quantities for them to consider while entering the demand quantities.

- Consolidation/ Aggression in a single window for Division heads, Region Heads or Marketing Team to view.

- Role-based authorization to view, edit quantities.

- Remarks or reasons and be provided for high or low demand quantity.

- Visibility of Inventory levels, replenishment, deployment of products and In-transit quantities across depots and plants.

- Creating multiple exception reports from existing ERP to input data for demand planning.

Benefits:

- Forecast Accuracy improved from 55% to 75%.

- Sophisticated Statistical Techniques other than just 3 Months Average to predict trend and seasonality at Item – Region combination.

- Single unified system to collate data from Area Sales Manager and compare with Statistical Forecast.

- Robust processes to efficiently manage dispatch planning and safety targets